High Performance

Bio Carriers

for biological waste water treatment

and gas treatment

Quality made in germany

DIN EN ISO 9001: 2015

Hel-X Bio Carriers in biofilm and mass transfer processes

Hel-X biocarrier are specially developed for use in biofilm processes. They are used successfully around the world in municipal and industrial wastewater treatment, aquaculture / aquaponics, and ornamental fish farming as growth bodies or fillers. You will also work in numerous other areas of process engineering as fillers in mass transfer processes.

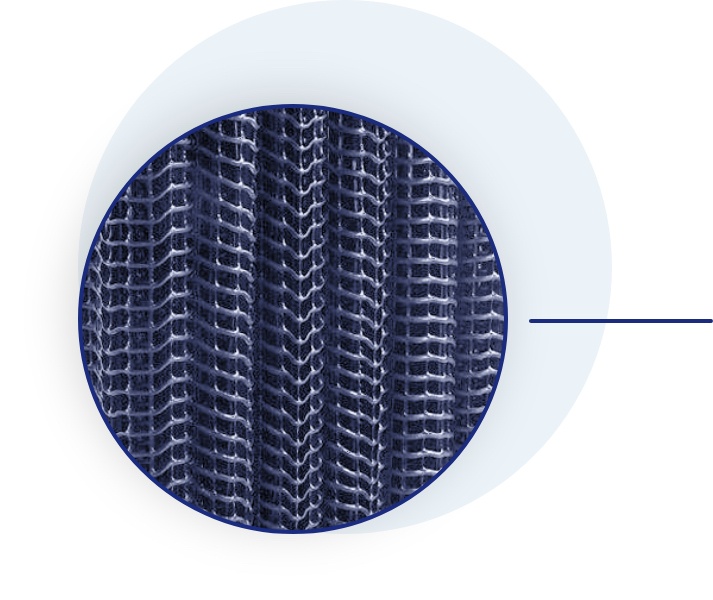

The Hel-X Flake is a further development. The extremely large specific surface of this product results from the porosity of the material.

All Hel-X products are manufactured in Germany according to our quality and environmental standards.

The name Hel-X characterizes the circumferential spiral or helix, a product property that ensures high mechanical stability with at the same time very good flow and a high specific growth area. The biofilm is optimally supplied with oxygen and nutrients.

News

Bavaria's strongest medium-sized companies

Christian Stöhr GmbH & Co. KG will be in the top 10 again in 2024

Anniversary: Ms. Bätz Celebrates 10 Years with Us

We are pleased to celebrate the ten-year work anniversary of Ms. Cindy Bätz! For a decade, she has been an indispensable part of our finance and human resources departments.

Managing Directors Henry Stöhr and Michael Stöhr had the honor of presenting Ms. Bätz with the IHK certificate of honor. Her dedication and professionalism have significantly contributed to our success. We thank Ms. Bätz for the excellent collaboration and look forward to many more years together.

Our Team at the IFAT in Munich

Thank you for 25 years of excellent cooperation

Top 10 of the strongest Bavarian medium-sized companies

Creditreform Rating AG rates a total of 2,281 medium-sized companies on behalf of the SZ Institute.

Christian Stöhr GmbH & Co.KG occupies an excellent 8th place in the ranking “Bavaria’s strongest medium-sized companies”.

Small and medium-sized businesses are considered to be the engine of the German economy and contribute significantly to the economic strength of the region, especially in Bavaria.

For more information on the selection of the companies examined and the criteria of the study, please see the link below.

The results of the ranking were published on May 10, 2023 under the title “Bayerns stärkste Mittelständler” in the print edition 107/2023 of the Süddeutsche Zeitung and online (Link).

New! HEL-X Flake PRO

Hel-X Flake Pro

- profiled shape

- increased surface area

- improves growth – avoids adhesion of biocarriers

- efficient flow

applications

HEL-X Bio Carriers

Wastewater treatment

- industrial and municipal wastewater

- MBBR – moving bed biofilm reactor

- fluidized bed biology

Aquaculture

- Fish farming

- Circulation systems

- Koi breeding

Ornamental fish farming

- Floating bed method

- Fixed bed process

other areas of application

- Biogas plants

- Gas washing and cooling

- Exhaust air and exhaust gas cleaning

Hel-X Flake 30

Ideal for heavily loaded Sewage and compact systems

Due to its high porosity, the HEL-X Flake 30 made an extremely large area available for biomass growth. This allows very high degradation rates in the smallest of areas.

In the pores of the HEL-X Flake 30, the biomass is protected from abrasion. At the same time, the flat geometry allows an optimal supply of oxygen and nutrients.

The HEL-X Flake 30 is the optimal solution for heavily polluted wastewater. The highly porous, compact structure enables high space reduction rates for high cleaning performance on a small area. In the pores, the biomass is protected from the shear forces, at the same time the surface of the chip is cleaned by the shear forces, so that the supply of the immobilized biomass with nutrients and oxygen is ensured.